Welcome to Ningbo Kumsung Machinery Co., Ltd.

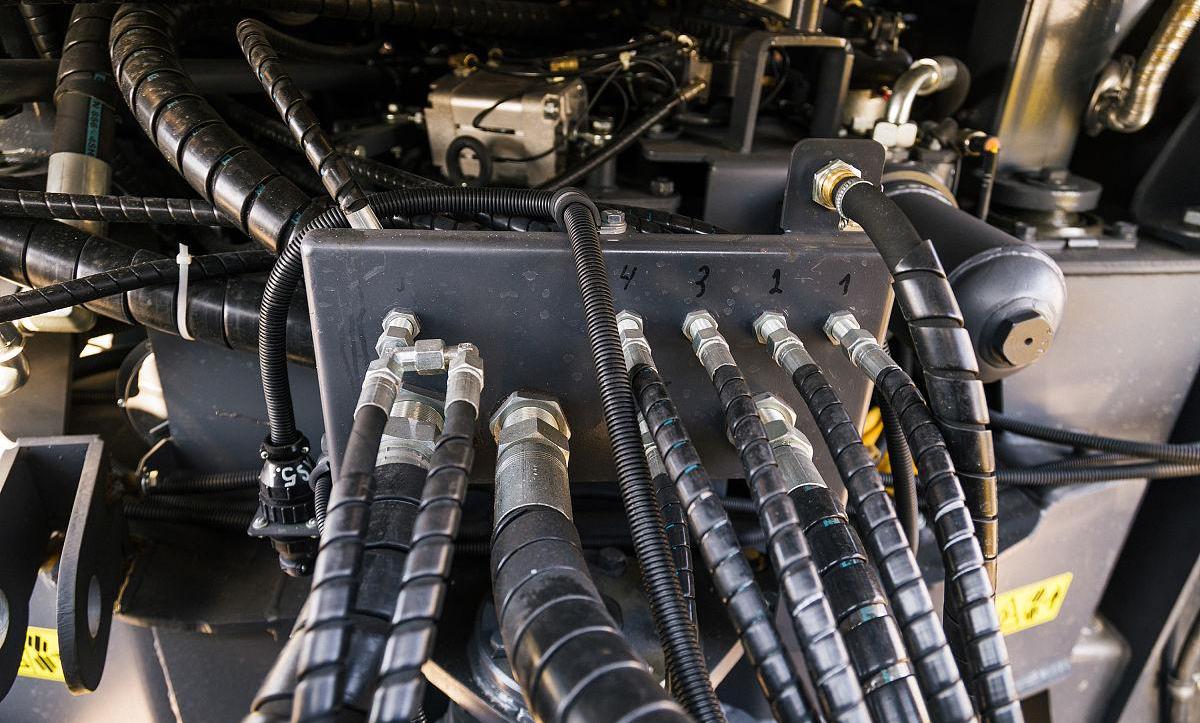

Hydraulic Oil Pipe Assembly: Understanding These Key Data to Make the Hydraulic System More Stable!

With the continuous development of modern industrial technology, hydraulic systems are widely used in various fields due to their characteristics of high efficiency and stability. As an indispensable part of the hydraulic system, the stability of the performance of the hydraulic oil pipe assembly is directly related to the operation status of the entire hydraulic system. How can we select a suitable hydraulic oil pipe assembly? The following seven key data will help you make a wise choice.

1. Dimensions of the Hydraulic Oil Pipe Body

The dimensions of the pipe body are the primary consideration when selecting a hydraulic oil pipe. Different hydraulic equipment has different requirements for the dimensions of the pipe body. If the dimensions of the pipe body are too large or too small, it may lead to poor operation or leakage problems of the hydraulic system, so it is necessary to make a selection according to the actual situation.

2. Pipe Body Pressure

The pipe body pressure refers to the maximum pressure value that the hydraulic oil pipe can withstand. When selecting a hydraulic oil pipe, it is necessary to ensure that the pipe body pressure can meet the requirements of the hydraulic system. If the pipe body pressure is insufficient, it may cause the oil pipe to burst or leak, seriously affecting the normal operation of the hydraulic system.

3. Thread Dimensions of the Joint

The thread dimensions of the joint are crucial for connecting the hydraulic oil pipe to other hydraulic components. Hydraulic components of different specifications need to be equipped with corresponding joint threads of the appropriate specification. When selecting a hydraulic oil pipe, attention should be paid to whether the thread dimensions of the joint match. If the thread dimensions do not match, it may lead to problems such as loose connections or leakage.

4. Form of the Joint Sealing Surface

The form of the joint sealing surface determines the sealing performance between the hydraulic oil pipe and the joint. Common forms of sealing surfaces include flat surface sealing, conical surface sealing, etc. Different forms of sealing surfaces have different sealing effects, and a selection needs to be made according to the requirements of the hydraulic system. Good sealing performance can ensure that the hydraulic oil pipe does not leak under high pressure, thus ensuring the stable operation of the hydraulic system.

5. Angle between the Joints at Both Ends

The angle between the joints at both ends refers to the included angle between the joints at the two ends of the hydraulic oil pipe. The magnitude of this angle will affect the layout and installation of the hydraulic pipeline. When selecting a hydraulic oil pipe, it is necessary to determine the appropriate joint angle according to the actual installation environment, so as to better adapt to the layout of the hydraulic system.

6. Joint Direction

The joint direction refers to the relative position between the joint of the hydraulic oil pipe and the pipe body. Common joint directions include straight-through and elbow types. Different joints can meet different installation requirements, ensuring that the hydraulic pipeline can be arranged more flexibly and conveniently.

7. Total Length

The total length refers to the distance between the sealing surfaces at the two ends of the hydraulic oil pipe. This length needs to be determined according to the actual needs of the hydraulic system. An overly long oil pipe will increase the system resistance and reduce the efficiency; while an overly short oil pipe may not meet the installation requirements. Therefore, when selecting a hydraulic oil pipe, it is necessary to determine the appropriate total length according to the actual situation.

In conclusion, understanding the above seven key data can help you select a hydraulic oil pipe assembly better and ensure the stable operation of the hydraulic system. When selecting a hydraulic oil pipe, it is recommended to consult professionals or refer to the technical parameters provided by the manufacturer, so as to more accurately meet your needs.