Welcome to Ningbo Kumsung Machinery Co., Ltd.

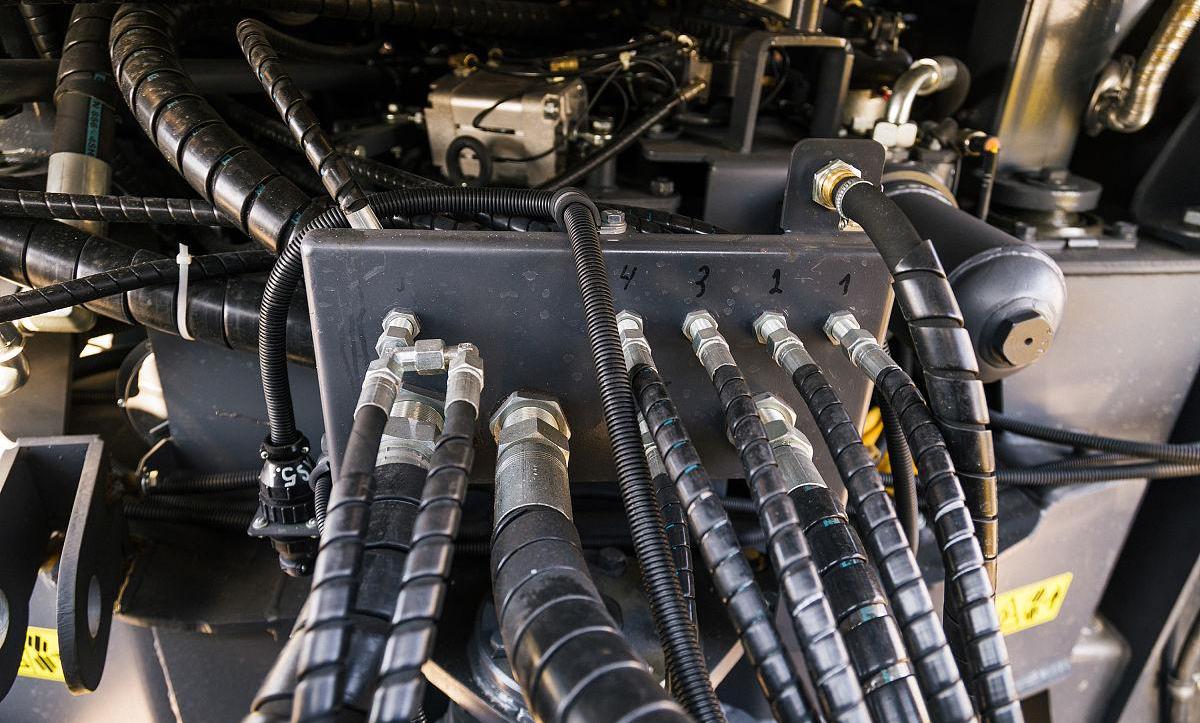

37° flared flange

- Tightly fastened to form a solid and stable sealing line of defense

- Strong connection through bolt fastening

- Well-suited to different harsh environments

In terms of appearance, it is in the shape of a disc, with a hole in the center and holes for bolt fastening distributed along the edge. The structural design is compact and practical. Its uniqueness lies in the 37° flared end at the connection part. During the installation process, the matching pipe fitting is inserted into the flared part, and bolts are passed through the holes on the flange, and the nuts are tightened to make the two pieces of the flange fit closely together. The 37° flare makes full contact with the outer wall of the pipe fitting, forming a reliable seal. This connection method can effectively prevent fluid leakage. Whether it is transporting liquids or gases, it can ensure the stability of the system pressure, providing a solid guarantee for the complex pipeline systems in industries such as petroleum, chemical engineering, and shipbuilding.

The commonly used materials for the 37° flared flange include carbon steel, stainless steel, etc. With its precise flared angle design, reliable sealing performance, and diverse material options, the 37° flared flange meets the pipeline connection requirements of different industries and working conditions, and has become an important cornerstone for constructing a stable and efficient fluid transportation network, silently promoting the smooth progress of production activities in various fields.